The Main Principles Of Recent Developments in the Use of Precast Concrete Units for

Sustainability - Free Full-Text - Hysteretic Response of Tilt-Up Concrete Precast Walls with Embedded Steel Plate Connections - HTML

What Does H C Walling Document - National Precast Concrete Mean?

The joints in between precast units or between precast and other building components should be preserved to prevent leakage through the precast wall system. Joint style must consider the structural, thermal, and all other aspects that impact the efficiency and movement of a joint. The joint seal ought to naturally be sufficiently designed to hold up against the motion of the joint.

Detailing Considerations - American Institute of Steel Construction

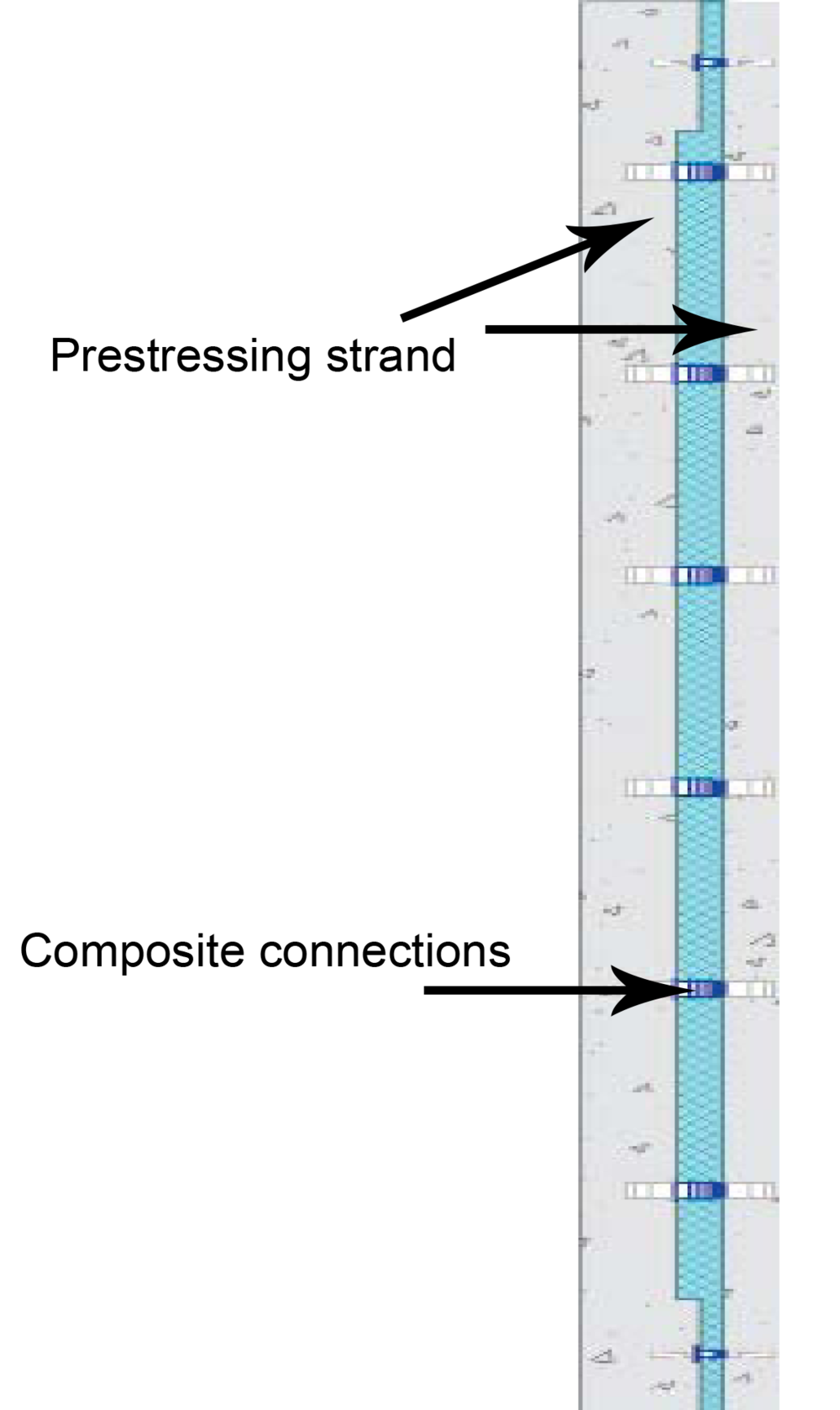

Basics Structural Aspects of Design Precast concrete wall systems are usually built as a drape wall or veneer, in which no structure loads are moved to the concrete panels. A lot of generally the precast concrete wall system must resist lateral loads straight imparted on it, such as from wind and earthquake; as well as vertical loads resulting from the self weight of the precast wall system.

Indicators on Panel connection details in existing New Zealand precast You Should Know

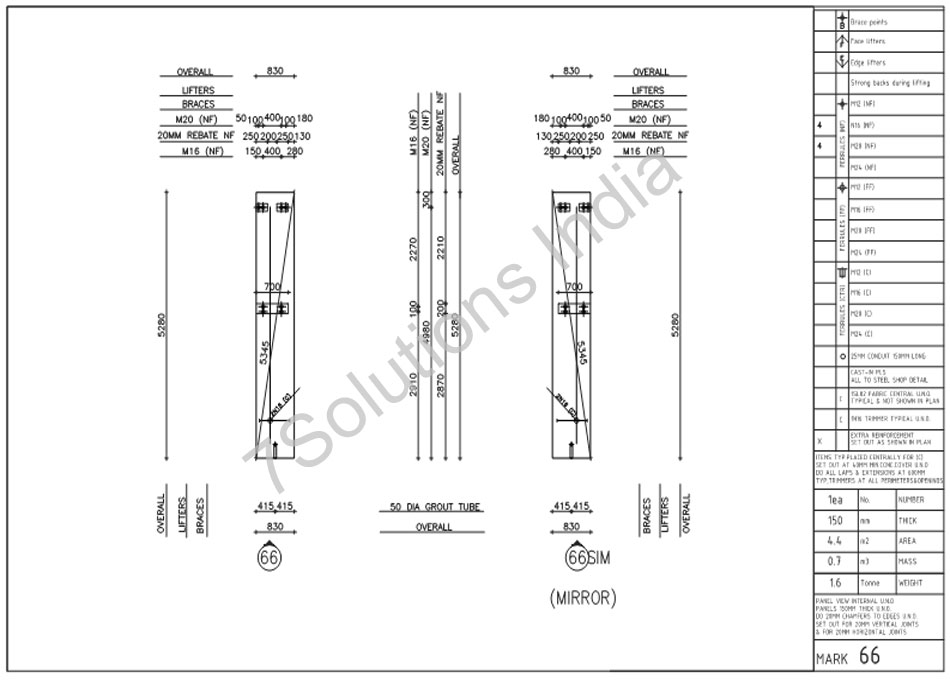

Other loads such as erection, effect, building and construction associated, and transportation must likewise be considered in the style. It is necessary to evaluate the style, detailing and erection of precast panels in order to avoid enforcing unwanted loads onto the panels. The concrete panels are developed in accordance with PCI Design Handbook-Precast and Prestressed Concrete (MNL-120), Design Obligation for Architectural Precast Concrete Projects (ACI 533.

Steel aspects of a wall system are created in accordance with AISC specs for steel construction. Read This are created in accordance with ACI and PCI requirements. Joints in between panels need to be wide enough to accommodate thermal expansion and differential movements in between panels. Joints in between panels are most commonly sealed with sealant to prevent water penetration in the wall cavity.

Not known Facts About Test and Finite Element Analysis of Gravity Load Designed

Efficiency Issues Thermal Performance Precast wall panels derive their thermal performance characteristics mostly from the quantity of insulation placed in the cavity or within the backup wall, which is commonly a metal stud wall in business building. Moisture Protection The most common moisture defense system used with precast concrete wall systems is a barrier system including a sufficient joint seal.

Sealers can be either clear or pigmented if used as an improvement of the precast appearance. Film-forming finishings typically use a greater level of efficiency but will have a substantial influence on the look of the precast concrete unit. The precast concrete panel must likewise be created to offer the proper level of durability for the organized direct exposure.